3d printer filament reviews

3d printers have now started to become part of everyday life for some.

Children now have the ability to visualise ideas and within hours have that idea in their hand.

Long gone are the days of just dreaming about a new product.

There are many filament types available for 3d printers. It is dependent on what you want to achieve.

There are standard products, flexible, metallic, water soluble, wooden, stone and many more.

This list of products reviewed here will be updated periodically – so be sure to check back – or signup to be told when it is updated.

We start with the most used product at present

PLA

Pla, or polylactic acid, is made from plant material. It can be extruded from starches of corn, cassava, sugar cane, cereals or sugar beet. The material can be biodegradable under the right conditions, active compost heap with enough oxygen. The material is ROHS and REACH compliant.

PLA can be made 100% opaque or semitransparent. It can be mixed with other materials such as wood, stone and cork to simulate the smell and

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

pla |

easyfil |

180-220 |

35-60 |

3310 |

1.24 |

Standard material |

Glow in the dark |

180-220 |

35-60 |

3310 |

1.24 |

Glow in the dark |

|

magicfil |

180-220 |

40-50 |

3310 |

1.24 |

Temp colour change |

|

Wood |

200-240 |

40-50 |

1930 |

1.2 |

30% Wood and cork filled |

|

stone |

175 smooth 210 rough |

40-50 |

?? |

?? |

0.65mm nozzle |

|

bronze |

190-220 |

60 |

3990 |

3.5 |

Bronze filled use 0.4 mm stainless nozzle |

|

copper |

190-220 |

60 |

4210 |

3.4 |

Copper filled use 0.4mm nozzle stainless steel |

The above table gives the temperature settings for the 3d printer, for both the printing nozzle and the heated bed.

The tensile modulus is an indication of the relative stiffness of the material. It is included in the tables to give a relative guide to the different materials stiffness not an absolute. The higher the number the stiffer the material. So all of the PLA materials are stiffer than the ABS, the ABS is a lot stiffer than the TPC.

ABS

ABS, or Acrylonitrile-Butadiene Styrene is a plasic manufactured from oil based material. As such it is non biodegradable. It can produce tough plastic object, it is used as car bumpers. There is a flame retardant material available. This material is more difficult to print with. The material is ROHS and REACH compliant.

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

abs |

absfil |

220-270 |

110 |

1860 |

1.03 |

Standard abs |

|

Abspro flame retardant |

240-260 |

110 |

2440 |

1.18 |

Flame retardant |

|

titanx |

240-260 |

110 |

2030 |

1.1 |

Increased strength abs |

|

clearscent |

220-260 |

110 |

1900 |

1.06 |

Transparent abs |

Pva

PVA, or polyVinyl Alcohol, is a cold water soluble filament able to bond to thermoplastics. This is mainly used as a support material for pla and abs. Used with multi-printhead printers, this material can be easily removed after printing by placing in cold water.

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

pva |

aquasolve |

180-205 |

60 | 3860 |

1.23 |

Water soluble |

atlassupport |

180-205 |

60 | 3500 |

1.22 |

Strong support water soluble |

Sbc

SBC, or Styrene Butadiene Block Copolymer, is a material which is strong, flexible and clear. It will allow 92% of visible light through. Due to its resilience and flexibility the material can be bent up to over double without white stress marks appearing. The material has excellent interlayer bonding and low warping due to the limited water absorption.

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

sbc |

crystalflex |

230-260 |

70-90 | 1795 |

1.01 |

Very clear |

Asa

ASA, or Acrylonitrile Styrene Acrylate, is a material which has great thermal stability and improved flow characteristics, allowing it to be used outside and within the automotive environment easily. The material is UV and weather resistant ensuring the the colour will stay at its best.

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

asa |

appolox |

235-255 |

50-100 | 2020 |

1.11 |

Weather resistant watertight |

Tpc

TPC, or Thermoplastic Co-Polyester has a flexural memory – allowing it the return to its original shape after being bent. The material is also strong, durable with a good resistance to chemicals. It is resistant to UV and extreme temperatures making this a very useful material for most applications.

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

TPC |

flexfil |

220-260 |

60-100 | 95 |

1.14 |

Flexible filament |

Petg

PETG, or Polyethylene Terephthalate Glycol-modified, is a material designed to be able to withstand a wide range of temperature, along with being a tough, strong transparent material.

The material is also manufactured with 20% carbon fibre reinforcement allowing even more strength, with added stiffness.

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

petg |

hdglass |

195-225 |

– | 1940 |

1.27 |

|

carbonfil |

230-265 |

– | 3800 |

1.19 |

Hips

HIPS, or High impact Polystyrene is a disolvable material used for the support of ABS. This material dissolves completely in limonene. For use in a dual extrusion printer.

material |

name |

Printing temp |

Heated bed |

Tensile modulus |

Weight g/cc |

notes |

Hips |

limosolve |

220-260 |

50-100 | 1550 |

1.04 |

Abs support material |

Other Information

One question which is not answered on the above tables is how much material do you get on a reel?

Well, taking the easyfil PLA with a weight of 1.24g/cc . A 500g reel will consist of 500/1.24 = 403.226 cc of material.

So you now have the volume of material on the reel. Some models tell you the volume and others state the length of material you need.

So how do you gauge whether you have enough material?

If the material is 1.75mm diameter and the area of a circle is pi*r^2

If d=2*r, d being the diameter

And A = pi*r^2, A being the area

Solving for A

r=d/2

A=pi*(d/2)^2

A=1/4*pi*d^2

A=0.25*3.142*1.75^2 = 2.4052

So in a 500g reel we have

403.226/2.4052 = 167.66 m of material.

If the weight changes, like it does for abs to 1.03 g/cc we can recalculate the volume of material or scale the above.

We used 1.24 g/cc the new weight we use is 1.03 g/cc

So the scaling factor is

1.24/1.03 = 1.2039

Multiplying the original length by 1.2039 will give the new length

167.66*1.2039 = 201.84m

Or going back to the original calculation – the area stays the same but the volume of material changes.

The new volume is 500/1.03 = 485.43cc

This divided by the area

485.43/2.4052= 201.82m

So you can see both methods tie up within a small error.

Using these methods you can quickly calculate the length that is going to be supplied on a reel.

Hints and tips

Once you have purchased your filament – keep it in the sealed bag until you want to use it.

Open the bag carefully and reseal the filament into the bag after use – getting rid of as much air as possible. Leave the bag of silica gel in the bag to absorb the moisture.

Your filament will absorb moisture from the atmosphere gradually over time. This, when heated will bubble and possibly cause voids in the extruded material interfering with the flow, creating holes in the model. Use of the vacuum storage bags will reduce the water absorption from the atmosphere.

When trying a new filament, get a test model from Thingverse, or design your own. It only needs to be three of four layers and about 1” (25mm) square. This will show whether the temperature of the nozzle is correct, whether the model is going to adhere to the plate and what the finish of the model will be. Adjust to correct any problems with this model and you will have less problems when you come to print your final creation.

Keeping careful records of what settings you changed for what materials and whether you had any problems with the printer will assist you in solving any issues you have with the models.

Get a piece of plastic the correct height to allow easy levelling of the bed. Keep this in the record book so you know where it is.

Thanks for reading

Phil

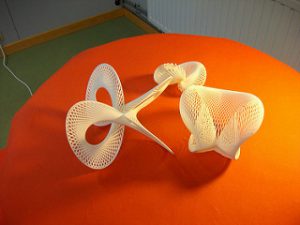

photo credit: A little classroom exhibition via photopin (license)

I never use a 3D printer before but I definitely would love to try and use one. They look like fun

They are fun Arthur, they can also be time consuming.

A lot of the tech is there but it doesn’t always work together, this is when you need a bit of patience.

Finding out whether it is the model you have created that has a problem or is it the hardware.

But yes they are definitely fun, and will get easier to use in the future.

Phil