Are you a destroyer or a detective?

You know what it is like when you have 3d print problems.

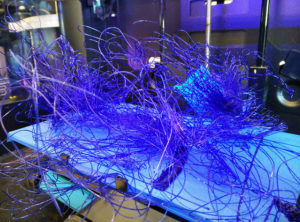

You come back to the printer after waiting 12 hours only to find this heap of spaghetti.

ARGHHH!!!!!

You rip it off the printer and throw it into the corner – where it bounces back and sits on the floor laughing at you!!

I know the feeling – I have been there many times – and yes I have done the same.

But after a while you get to thinking – if you don’t change anything you will get the same results.

So what should you do?

Become a detective, treat it like a crime scene.

Well, if you start recording what your settings were at the time of failure – or the last time you saw them then you might stand a chance of not making that error or having that problem in the future.

Am I saying it is your fault – no – it is a process problem. And any manufacturer worth his salt will have a failure reporting process.

Yes, you are a manufacturer of plastic widgets!

This is not a blame process but a learning curve to get the results you want.

So how do we go about it?

First thing is to make the printer safe.

If necessary switch it off, but before you do take a note of the temperatures.

The hotend temperature and the bed temperature. Take a picture.

And how the printer is sounding – if it is still running. Take a video.

Are all of the fans working.

Is the filament still going through the extruder – put your fingers on it gently and feel the filament move.

Are the motors working.

Is there any smell you don’t recognise ( filament burning, hot electronics, burnt electronics, rubbing belts)

Now switch off the printer.

Quickly touch the stepper motors – are they hot – very hot – or use a non contact thermometer.

Is the print still on the bed – I have had prints that have come adrift from the bed and ended up on the floor.

Leave the print on the bed – take a picture of it so you can see where it sat on the bed.- yeah I know it is a painful record of failure, but you hopefully can learn from it. You can also see if it is only one axis and which one.

Before you take the print off the bed mark it with the axis, if you can. This makes it easier to orientate the model once it is off.

Look at where the head is and see if it is catching the print. Or is the filament cooling nozzle catching the print.

Is it a layer shift? Does the model slide off to one side.

Are the belts tight?

Is the model suffering from elephants foot ( where the weight of the model and the heat of the bed has allowed swelling on the lower layers)

Is there blobbing, where the filament was too hot or not cooled enough after it left the nozzle.

Has the model warped – is there a draught ( window open) or too much cooling from the fan.

Has the filament stopped coming out of the nozzle

Has the filament on the spool crossed over causing it to prevent feeding

Have you pushed the limits with your slicing? Creating ovals where you thought there should be circles. Not taking any notice of any design rules of nozzle diameter.

I created a model the other day which I printed out at 0.2mm z height. Thinking it would look better with a finer step I changed it to 0.1mm z height and found that it started acting strangely, the print looked a lot worse with bumps and stringing, still investigating that one to try to find the cause.

If you go through and look at every print you do -even the successful ones and record the settings you will get to know your printer and possibly see when things are going wrong and repair them before a catastrophic failure happens.

The more you can record the more chance you have of finding out what has happened. Think in terms of a crime scene. You need to get all of the information before it is destroyed. Then sit down and go through possible scenarios of what could have happened – crossing out the ones you find that you can explain it is not.

Why not download a simple form for you to fill in, this gives you a permanent record of what hapened.printer problem sheet

You are becoming more of a detective, looking at the evidence and trying to piece together what has happened. to your latest creation.

It maybe down to the model was too high for the size of the footprint on the bed. It simply fell over with the shaking of the bed. I have had this in the early days, when I thought it was ok to build upwards without building out on a Prusa clone. You can get away with this on a printer which has a stationary bed – like a Renren3d delta, but definitely not a cartesian printer which tries to shake itself to pieces every time you print something out.

What do you do with your 3d print problems

So how do you deal with your failures? Do you just throw them away and take no notice, learn nothing from the valuable evidence. Or do you become a detective and examine every print and keep good records, learning as you progress with your printer. Trying to improve your chances of success and having a well maintained printer unlikely to have mechanical failures. Leave a comment in the box below about how you deal with your 3d print failures.

I hope this post has allowed you to see the possibilities of improving your 3d print problems.

Thanks for reading

Phil