What is the Bowden tube on a 3d printer for?

On a 3d printer, to achieve the prints you feed filament to a hotend for extrusion.

To achieve this there are two main extruders, bowden and direct.

The direct extruder has the motor mounted next to the hotend and the filament feeds directly from a motor to the hotend.

With the Bowden extruder the motor is mounted away from the hotend, and the filament is fed via a tube – normally PTFE- to the hotend.

This post details replacing the bowden tube on a 3d printer.

When you have jams, blockages and failed prints you start to look at your printer parts with a sigh.

If your Bowden extruder motor is jumping due to not being able to feed the filament up the Bowden tube then it may be time to replace it.

Removing the Bowden tube from your 3d printer

Prior to removing the old tubing use a piece of tape to mark how far the tube has been inserted into both ends.

With a Bowden extruder with quick connect pneumatic connectors you will need to depress the top piece around the tubing before trying to pull it out.

Failure to do this will result in permanent damage to the tubing.

Examine the end of the tubing for defects like ovality, burrs and damage.

Any of these may cause the filament to drag and cause printing problems.

Removing the tubing from the hotend may show that it has been heat damaged.

If there is enough length left you may be able to trim the end before refitting.

If the length is too tight you will need to replace the tubing.

The ptfe tubing is sold in standard lengths of 0.5m. You may not need a full meter to fit on your printer but you may need more than 0.5m. So order a 1m length and cut it to length.

Cutting the Bowden tube to length

Ptfe is known to be a soft material, but has excellent low friction properties.

This, along with its heat resistance, is the reason it is used.

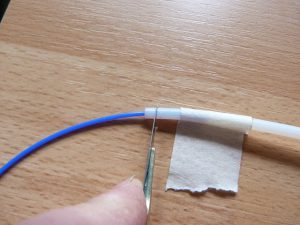

To cut your ptfe tubing to length use the old length as a guide and put a piece of tape around the new tube at the end of the old ones length.

If you use a knife to press down on the tubing you may deform it.

This will cause filament feed problems.

So what is the solution?

What I do when I need to cut the ptfe tubing is to place a piece of filament inside the tubing to prevent it from deforming.

This way you can run the knife around the outside and cut it cleanly with no damage.

Refitting the bowden tube on a 3d printer

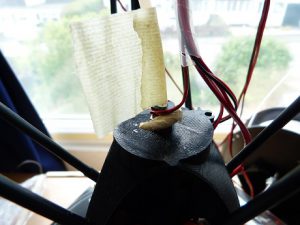

Once the ptfe tube is cut to length you will need to refit it.

To carry this out what I will do is to feed some filament into the motor gear until it comes out where the tubing is to fit.

The tubing is then placed over the filament and slid down to the quick connect coupling.

If you marked the distance the end was inserted now is the time to transfer that marking to the new tube.

The top of the coupling is depressed and the tubing fed into it.

Once resistance is met then stop pushing.

The motor gear end you should have fed about 10mm ( about ½ in) in.

The other end of the tubing is fed into the hot end.

I will mark the tubing with tape about 60mm ( approx 2 ½ in)back from the end.

If you have marked the old tubing before you took it out now is the time to transfer the marking over to the new tube.

This ensures that the tubing is fed into the hot end down to the correct depth.

As with the other end press down on the top of the quick connect coupling and feed the tubing into the hotend.

Keep feeding the tubing into the hotend until most of the marked piece has been fed in.

This ensures that it will be seated properly.

Failure to seat it properly may cause a filament jam.

You now have a new bowden ptfe tube fitted and know that this is not the cause of any print failures.

If you have had problems replacing the bowden tube on a 3d printer please leave a comment in the box below.

Many thanks for reading

Phil