3d home printers have come a long way since the late 80’s when the first printer was shown to the world.

So if you are looking for a 3d printer what questions should you ask?

Let’s have a look at some of the more common questions people have about 3d printing.

Like…

How large do you want to print?

Do you want more than one colour?

Do you want to build it or just print?

Are they difficult to operate?

How long does it take to print?

Let’s have a look at these questions in more detail.

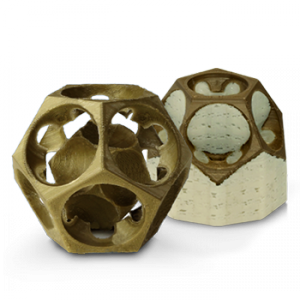

What do you want to print?

Ask yourself this – as I did, and you will probably say dunno, everything!!

You see all of the models when you are researching the printers on Thingiverse or youmagine and other sites where they are downloadable. You think, that would be brilliant, I need one…

What about looking around you and seeing if there are things you really want to print. Covers for the light switches, a new stand for your phone.

Ok, so the models listed here are not unreasonable, they will fit within the footprint of the standard 3d printers.

How large do you want to print?

If you had come up with a new frame for my bike, a go-kart chassis, a new chair. All of these are possible but will be way more expensive. You may need to clear out the garage to fit the printer.

But a standard at this time (Dec 2016) would be about 200mm cubed. Above this you start to limit yourself to speciality printers.

Do you want more than one colour?

The bulk of the 3d printers at the moment are single nozzle printers. This means that usually you will be printing in one colour. You can change the filament ‘in print’ but you need to be present within a certain time of the print pausing.

Two nozzle printers are becoming more common, you will then have a choice of using the second nozzle for a support medium or a second colour.

More than two nozzles are going to become more common but are pushing the price up significantly at the present time.

With the extra number of nozzles the print volume reduces or the printer gets physically bigger.

In the future I reckon there will be a different type of printer designed to cope with more than one nozzle and keep the volume of the printer down to a reasonable size.

How much space have you got?

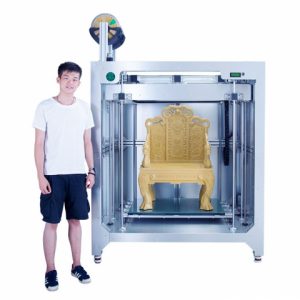

There are printers on the market which can print full scale chairs.

Yes they are expensive, but they are available. Imagine printing off unique chairs for your wedding or special party. A life size statue of yourself.

3d printers are quite large compared to where inkjet printers have got down to. Most 3d printers are the size of a large laser printer, and you need access all around the printer – or at least be able to pull it out to get to all sides.

The size of the printer is limited by the build volume. If you want a reasonable model size then the printer will be large.

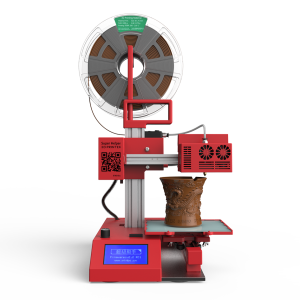

Do you want to build it or just print?

There are DIY model on the market, if you are good at building things this is a way of finding out how these printers work. You will build it up and start printing only to find out what is important. What really needs to be tight and how things align.

Is it really difficult – no. Follow the instructions and you will have put together a 3d printer.

If this is of no interest then you can buy a printer ‘off the shelf’ to suit. You will pay a bit more, but that is for the convenience.

Can you really take the printer out of the box and within a couple of minutes be printing? Yes with some, but as with standard printers they will requires some assembly.

Are they difficult to operate?

3d printers have become a lot easier to operate in the last few years. The software is a lot easier to use, you don’t need to be a programmer to operate the machine.

You download the model you want to print. You pass it through a slicer – this is how the printer knows what to do with the model. So the same as a printer driver. You then upload it to the printer, either by WIFI, cable or SD card. And then print.

Loading the ‘cartridge’ – or filament on some models can be tricky, on others it is almost automatic. So it it dependant on manufacturer.

Removing the model after printing can be interesting. You will ideally need to wait for the build platform to cool down to prevent distorting the model. If you have used glue to improve adhesion you can soak the model in water as long as the build platform is removable.

It is different to a inkjet printer or a laser printer but it is not difficult.

How long does it take to print?

It does depend on the layer resolution you print at- similar to an inkjet printer set to draft or to photographic quality, this will also vary the time taken.

The smaller the layer resolution the longer the print time. But the better the print quality.

The FFF (Fused Filament Fabrication ) method of printing slices the model into layers and dependent on the resolution set by the user, this defines the number of layer and therefore the time it will take to print.

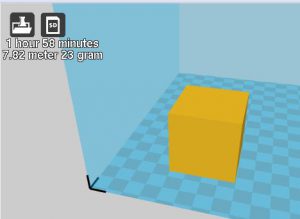

The slicer software normally will give an estimation for the length of time to print the model, along with the length of filament required and the weight.

Some typical guidelines – for a prusa i3 0.3mm nozzle 0.2mm layer height (draft print) will take 20 minutes and use 1.27m of filament.

With a layer height of 0.06mm ( photographic) the print time goes up to 63 minutes and takes 1.29m of filament.

Going up to a 40mm cube it will take almost 2 hours in draft mode and 6 and a half hours in best quality. Using 7.8m of filament.

How much does it cost to run?

So with the length of time to print, the next question that springs to mind is how much does it cost to run?

The printer electronics work from low voltage, the mains is scaled down to 12v before being applied to the printer by the power supply.

Most of the printers are fitted with a 12v 20A power supply, if this is run at maximum capacity constantly it would consume 240W – so in 4 hours it would use one unit of electricity (assuming 1 unit is equivalent to 1kwh). But the printer will consume a lot less than, there are quotes of printers using 30w average power, meaning that it would take 33 hours to use a unit of electricity. So even at 60w it would take 15 hours to use one unit.

The filament is sold by weight, 0.5kg or 1kg reels. This tends not to help when you are trying to see whether you have enough length of filament left to print your latest model.

To give you a gauge of length, for a 1kg reel of pla you are looking at about 333m of 1.75mm filament.

With the variation in weight of the different materials you will vary the length. See my post here for more information.

As a reel of PLA is about £15 for 1kg (Dec 2016 price) the cost per meter is 4.5p.

So the above 20mm cube would cost approx 5.7p and the 40mm cube 35p

Hopefully this post has answered what questions should you ask about 3d printing, if you have any others please leave them in the comments box below.

Many thanks for reading

Phil