What is 3d printing technology?

Just imagine a box – how do you see it in your mind?

Is it just a square?

Does it have depth?

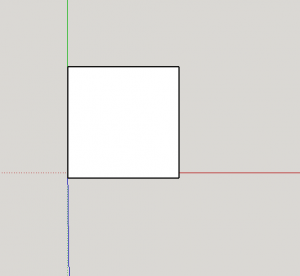

You can draw this in a CAD package in two dimensions, represented by a square.

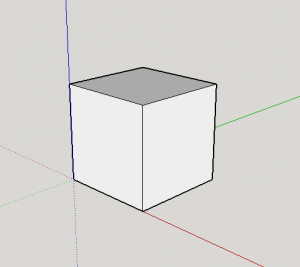

It can also be drawn in CAD in 3d, in isometric form, you can see the object has depth.

When you print this on a standard printer you get a flat sheet of paper with an image on it. You still have to use your imagination to ‘see’ it in 3d.

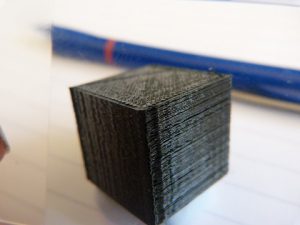

When you move over to 3d printing technology, after finishing the print you are able to pick up this 3d object that has depth.

You can rotate it see all of the sides. Feel the depth of the object and put it onto a surface and see the shadow it casts.

The progress from a paper print to a 3d print is an amazing achievement in engineering, the concept is simple but actually achieving the end result reliably is an amazing engineering achievement.

The actual process of printing in 3d is to take the object you want to print in cad and slice it into layers. The thickness of the layers is dependent on the type of printer or the extruder of the printer. Once sliced the information is sent to the printer.

Within the printer is a controller similar to the inkjet printer you are used to, where the print head moves sideways across the page. Except that the print surface can move back and forwards.

This left, right, back and forwards movement allows the printer access to the whole of the build platform.

For every slice layer the print head moves a little bit further away from the print surface, thereby building up the model in layers.

It is a fascinating process to watch and can consume hours of your life. Or am I just sad?

What can you achieve with 3d printing technology?

There used to be only a couple of choices of materials, PLA and ABS.

PLA is made from corn starch and is biodegradable, ABS is the type of plastic used for your bumper.

The industry has now woken up to the fact that it is becoming more mainstream and the public want more materials and choice of materials.

So now you can print a printed circuit board. The whole lot. The base material and the conductive tracks.

You can then design the box it is going into and print a rugged box out of a flexible material. In fact the printed circuit board can become the inside of the box.

If you need a window to see a display then there is transparent material.

Unfortunately at the moment the home printing technology is lagging behind as most are fitted with only one nozzle. Meaning that you need to change the material yourself as opposed to placing all of the different materials on the printer and pressing print.

So with home based printers you can start to print fantastic items. There is a little way to go before you press a button and a complete multicoloured, multi-material print that is available within minutes.

What can you print with a 3d printer?

A few years ago in 2013, 3d printing was thrust into the limelight when Cody Wilson, designed and printed a working 3d printed gun. The files for this were distributed on the internet and a short time later the U.S. Government took down the site, but not before over 100,000 people downloaded the plans.

Medical research into printed body parts is increasing, allowing body cells to be printed into ears and noses. This is in the early stages but progress is being made.

Imagine walking into a restaurant and looking at a menu where you can design your own food. This order is then taken and a few minutes later your order is served exactly like you designed it!!

Airlines are starting to look at this technology for storing food onboard the planes until the time comes to print and cook your meals.

The latest jewellery fashion can be downloaded and printed, if you are going to a themed party imagine being able to print off the items you want for the theme.

At the RIO olympics:

There were 3d printed shoes presented to Michael Phelps.

the French cycling team used 3d printed handlebars.

and one area where 3d printing will excel in the future – prosthetics. German paralympic cyclist Denise Schindler had a prosthetic leg printed.

At home you are only restricted by the amount of time you are willing to devote to learning CAD and sourcing materials.

There are a few home extruders available for the home experimenter to try combining different materials.

At present there is a wood effect PLA along with a stone effect, two different textures can be achieved with the stone by using different temperatures. But new products are being developed all the time so by the end of the year there will be a lot more.

What is stopping the take up at present?

The lack of simple inexpensive consumer printers, with lack of suitable materials is a big stumbling block to mass takeup of these types of printer.

Over the last five years there have been fantastic developments in the 3d printing market allowing the public to buy and print 3d models.

The models can be downloaded from sites like Thingiverse, Youimagine and Pinshape.

If you want to go further than this you will need to learn how to design and process the models. This can be time consuming, or you can ask one of the design houses like Shapeways or Scutpteo to model what you want and then download and print the item.

The speed of the printers will need to increase, print times of up to 24 hours are not unknown at present. The limitations are how fast the nozzle can move around the build platform.

The size of available build platform needs to be addressed. At present a lot of the printers have a small volume build area of less than 200mm X 200mm X 200mm. A lot can be printed within this area but when you are looking at printing a new large flower pot you are restricted to the build volume without making the part in pieces.

The physical size of the printers, the build volume on some printers is doubled by the movement required. Along with the required height of over 350mm on a bare printer with the enclosed printers taller than that.

How the industry will address these problems is yet to be seen, but small compact printers are being produced along with large machines, if you have the space and deep pockets.

3d printing is a technology which is starting to affect a lot more of our lives, the benefits are endless. It is a technology that the smart consumer would be ready to use as the product mature. It is an emerging market.

Hopefully this has given you an insight into what is 3d printing technology and what it can achieve, if you are using a 3d printer please tell us what you are using it for and what developments you would like to see in the future.

Thanks for reading

Phil

I think I understood a little what a 3D printing is. It’s pretty cool to print out an image that has depth.

You can also rotate it to all the sides and see a shadow. That’s pretty amazing. I would have loved to learn how to do that.

Do you know how to use this printing?

Tove

Hi Tove – thanks for stopping by

To watch a 3d printer for the first time is amazing.

Seeing what you have seen on the screen actually appear on the build platform, being created in layerrs, wow

It brings a smile to my face every time i print something out and remove it from the build platform.

I am currently learning how to use the software to produce items ready for printing.

It really is revolutionary to be able to design and print items to repair broken things almost like star trek.

Phil