A lot of people look at the small volume of the desktop 3d printers and dream of designing a huge machine.

What limits the size of a 3d printer: mechanical components , complexity and costs are the three main limitations for the size of a 3d printer.

In theory there are no limits to the size of a 3d printer, but practically there are a few — let’s have a look at some of them…

What do we have right now

Your typical home desktop 3d printer has a volume of 20cm X 20cm X20cm for the x,y,z sizes.

This equates to 20x20x20 cm^3 = 8000cm^3

I know i have dreamt of building a huge , and i mean a huge 3d printer…

One that no one else has thought of building….

The stepper motors can be just the same….

As can the electronics….

And it will print chairs and tables with the same resolution as what i have now…

Ok…back out of dream land let’s look at some of the large printers around now and see what their specs are…

What are large format printer

So you want to print big huh…

Well you could easily go up to the Tronxy X5st with a build volume of 500 X 500 X 500 for about $700 – but that is not that much bigger…

Or the MODIX BIG-120X v3 with a build volume of 1200 X 600 X 640 for $6500, still not big enough…

How about the THE BOX from BLB industries a massive 1500 X 1100 X 1500 for a bargain price of $50,000 ( 2020 prices).

Mechanical limits

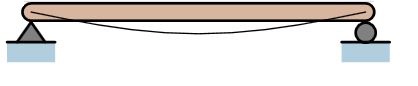

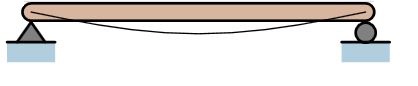

Your little desktop 3d printer with a build volume of 8000cm^3 uses 8mm straight rods over that span.

And you can bet there will be a little sag in the center.

Now double the width and that deflection becomes very serious with the weight of the printhead.

So you thicken up the rods to 2X the diameter – so that’s now 16mm diameter rods.

The frame needs a bit more bracing with the weight increase.

And the belt is twice the length – you know how difficult it is to tension that standard belt – now you want it twice that length….

More stresses on the frame sides…..

The bed is now twice the width, so double sized. the weight goes up so the speed you can throw it around comes down…unless you uprate the motors and electronics….

And if you decide to increase the y axis then the bed is four times the size and weight …

Imagine trying to get that bed flat to within 40um over that distance and support it underneath…they struggle enough with the standard bed never mind one 4X the size…

And double the height – getting rods that are straight over that distance and increasing the leadscrews diameter….

And ideally an enclosure to keep the temperature stable to reduce the warping of the models…

So all around the mechanicals have to increase to keep the accuracy and that is only going twice the size…

Imagine 5X the size.

Besides not fitting onto your desk, the shear bulk of the mechanicals is getting so large that it is time to look for a different way…

For me it is individual sections, so maybe robot arms with an overlap – controlled from a central processor reducing the likelyhood of arm crash.

This way the different sections could be printed at once rather than sequentially…reducing the timescale of the large print size.

Electronic limits

Upsizing your printer may mean upgrading the size of your steppers – so upgrading your stepper drivers.

And you will need the stepper to get to the other side in almost the same time as now – so a massive increase in the speed and getting all that mechanics moving….

Again an increase in stepper motor size….

You will need an increase in the processing speed – so out goes your faithful old arduino…

Your power supply – on the limit for the old Anet a8 would be one part which now is huge – so power usage becomes a significant percentage of the costs.

Along with volume of printing material…

Are the slicers up to it

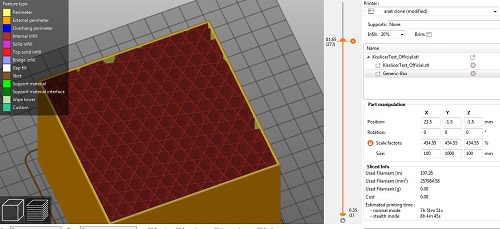

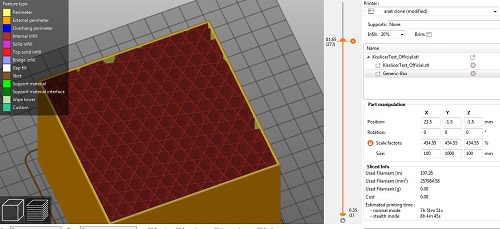

To 3d print a model you need to slice it and create a gcode file.

So let’s take a 25mm cube and slice it with 0.3mm slices – the time according to cura would be about 20 mins at about 60mm/s print rate

So keeping the speed setting the same lets double the size to 50mm all round.

The time has gone out to 102 minutes…..

To get back to the 20 minutes we need to increase the speed to about…well the slicers are internally limited in the software and won’t allow me to carry on increasing the print speed so i can’t get it below 82 mins

And double again to 100mm cubed the time has gone out to 7 hours and 51 mins (471 mins), even at the higher speed…

So you can see that even a fourfold increase in size and a massive increase in speed the timing has gone out by 22 times…

The other way is to increase the nozzle size and then increase the layer thickness.

But if you want fine detail on the outside then you need the precision nozzle.

Maybe this is something they can look at in the future – printing on surfaces rather than printing the whole model, so 3d printers become surface decorators.

With this you maybe able to have the large layer heights and then finish off with a finishing printer.

Is there any future for very large printers

As can be seen from the figures above – to get to a meter cubed you are looking at a very serious printer – industrial – enclosed and heated to keep it stable – very heavy mechanically to get the precision.

Will they go up much from this and get the precision.

I very much doubt that they are cost effective enough for a manufacturer to try.

The time taken to print such a volume must be huge, it is getting into the territory of cnc timing – so decisions will be made whether to remove material (CNC) or use additive manufacturing (3d printing)…

With the idea of the multi arm printers – you are adding a lot of cost and complexity, it would be unlikely that home users would have access to this sort of tech for a cheap price.

The same with the finishing printer.

Maybe the large layer height bulk printer, but the finishing printer would almost have the agility of a robot arm to get into all of the nooks and crannies.

So there is a limit of build size versus cost and builders of 3d printers are finding this whenever they build a large volume printer.

If you can sacrifice resolution then you can build larger, but if you want the really small feature size then you will have to put up with printers being about the size stay are at the moment until a massive breakthrough in tech happens.

You might find large fast printers at 3d print service centers, along with metal printers.

But for printing , and scanning, large objects on a fixed bed i feel that the problems will outweigh the benefits for a while to come…