While looking around for 3d printer project ideas, I had said to myself that I would make, as far as possible, useful bits!

So I am starting a series of ‘how to design’ repair parts, how to think the problem through. How to use the software to get the desired results.

This may be what you are already thinking through, without realising it or you may be just downloading and printing. Either way is good, but if you can design simple parts to repair items that have broken – even better.

We have a tall salt and pepper grinder – two separate items.

A while ago while using the salt grinder a small piece of plastic fell onto my meal.

I didn’t think anything of it until I went to fill it up.

The bottom fell out!!

The rod with the grinder just dropped. It had never done that before!!

On closer examination the piece of plastic that had landed in my meal was a keeper which, when the top nut was undone kept the center rod from falling through.

We had a smaller one to use in the meantime and the tall one was put to one side – other than that it worked ok, the important piece was in good working order so why throw it away?

It is now about 12 months later and it is time I looked at the salt grinder.

Turning it over there are two screw holding the lower piece in.

Removing these the lower piece drops out.

The screwed in bit is made up of two pieces, an outer plastic piece and the inner ceramic grinder part.

The outer plastic piece is not really any use any more – just holding it there are pieces falling off. The salt has completely corroded it. Not the normal corrosion but it appears to have changed the structure of the plastic and it is crumbling away.

Now being careful, I extracted the inner ceramic piece without damaging the outer too much.

I need to draw up the outer, to remake it in 3d printed plastic. Will this survive the salt atmosphere? Don’t know – there is very little data on the survival rate of PLA in salt water. Although it is made from corn starch, I am still a little wary of contamination. But it will be a useful exercise to draw up the outer and at least print it off in readiness for more suitable material.

Taking out a note book and pencil – it’s still easier and quicker to do this, unless you have an all- in-one with integrated scanner – then you have the advantage over me. Just scan the object – make sure it is now hollowed out correctly then print it!!(well that’s the theory at least!!)

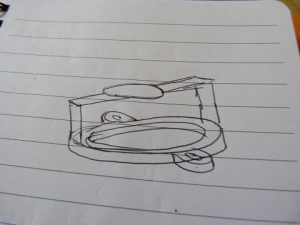

Up until the time I worked out it was a separate part I was looking to add a strap across the bottom, fixing it with the two screws. I would have rotated the strap through 90 degrees from the screws and affixed it onto a ring around the bottom.

See quick sketch for details.

So using Google Sketchup how do we draw up the piece?

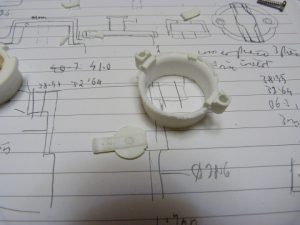

Turning the piece around you can see it is made up of discrete shapes. Tubes, rings, flat pieces so nothing too difficult – except it is the most complex part I have made with Sketchup.

A couple of quick sketches and I think I can simplify the piece from what is there, and thicken up the lower wall, always a bonus.

With things like this you need to look at how you are going to print them, if you get it wrong then there is a good chance an overhang will droop or even worse break. So with this piece print it from the bottom up with the strap at the base and it should be possible.

So taking a break from here until I have drawn up the piece I will post this and get back to you with the drawn up piece.

To be continued …

How would you have designed the piece – if you have any ideas then please leave them in the comments box below. Have you any 3d printer project ideas you would like to see me make, leave a reply in the comments box below.

Many thanks for reading

Phil