There have been a lot of questions about 3d printer slicer software, so i thought i would put pen to paper ( so to speak) and answer half a dozen of the top ones…there will be more to come…

Do i need a slicer for 3d printing

You need a slicer for 3d printing because of the type so instructions the 3d printer needs to carry out the print. This is the same on most CAD programs as they will only output certain types of files – the major one being the STL for 3d printing. This then needs to be converted into gerber instructions for your 3d printer to understand, and this is what the slicer does.

The slicer takes the STL file, information about your print material the filament), the printer and combines it into a format to extrude enough filament in the right direction in a layer format.

Can you use any slicer for 3d printing

As long as your 3d printer takes gcode then yes you can use any slicer file to convert the stl or obj into a gcode file.

As far as i can see all the major printers use the gcode format.

You will get used to a slicer, this may not be the best slicer for your printer for all prints as the way they process the gcode can differ for different models…

It is worth trying a few to see what works and what doesn’t…and which you like..

Can i change the speed on my 3d printer

There are two ways to change the speed on your printer…

One is to program it in the slicer with the availability to set the various different speeds for the different lines your printer will be printing…

The other is when you are printing, you can click on the menu button and select tune…

You can then set a percentage speed for the whole print…

So if you find that the temperature of the nozzle is dropping during the print, lowering the speed of the print may keep the temperature stable…

Can i print pla too slow

Pla or poly lactic acid polymer starts getting soft around 60C or goes through its glass transition temperature then…

But it doesn’t get molten until around 190C….

Taking the temperature up to 200C and printing quite fast >100mm/s may cause the nozzle to struggle to stabilize the temperature….

So you may think going slow will then be best…

But if the temperature of the nozzle is too high then you may burn the pla or you may get oozing as you are printing…

With the burning you may get hard particles breaking off form the wall of the nozzle and blocking or partially blocking the nozzle, this wil lcause a partially failed or completely failed print…

The oozing will cause blobs to appear on the surface of the print, with a lot of c

leanup afterwards…

So setting the speed and temperature right in your slicer is important…

The temperature of the nozzle can be altered or ‘tuned’ while you are printing, but the damage may be done…

Which leads into….

Does 3d print speed matter

The 3d print speed does matter with regards to your printer performance along with your materials

performance…

For you printer you will have a maximum speed for travel without the steppers slipping or missing steps…

When your printer changes direction there is a massive load on the printhead and travelling too fast can cause overshoot or worse slippage in one or both the X and Y direction, showing up as shifting layers…

It is worth getting to know your printer and setting these maximums within your slicer software or making a note of them and tailoring each print file gcode so that it stays at least 20% under it…this will allow for variations in temperature and materials…

How can i make my print faster

Optimizing the slicer settings will make your print as fast as it can be.

So finding out what your printer can do and working within this is the best way of producing the fastest prints you can….

But normally you only want to print as fast as you can for low quality prints and slow it down to get the high quality definition…

You need to look at the model you want to print and determine what sort of features it has, are they very small features or is it mainly straight runs…

Small features printed at high speed may have imperfections, but run at lower speed will be perfect…

There are some slicers that allow you to define areas of print, so the large featureless areas can be printed at high speed and high definition areas at lower speed…so this maybe an option if the model is large…

How do i change the seam position in Cura

Cura will position the seam in one line unless you tell it to randomize or start in a certain position…

Under the walls section ( in Cura 5.x.x) there is a Z seam alignment section allowing the user to have certain methods of creating the seam…

If you have one face where you can have the seam not shown then it is worth using the user specified option…you can now place it, say, at the back and this will place all of the start and stops at the rear of the model…

Or if you don’t want a seam as such then there is a randomize, which will place the start at random points to hide the seam…

Or if you can hide the seam on a corner then choose the sharpest corner….

Cura is a little limited in the selection of the start position…but one of these can help disguise the layer transitions…

If you want to really get rid of the seam then going through a setup of your printer may be the best…

Setting your linear advance in the printers software by printing a set of calibration lines will be the best way of ‘losing ‘ the seam…

Linear advance releases the pressure coming to the end of a line and pre-pressurizes the nozzle at the start of a new layer, so there is no gap between the stop and start.

I would also advise looking at the preview before printing…and maybe even using another slicer to import the gcode to have a look at what is going on…before you print..

This may prevent failed prints…

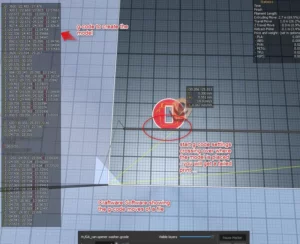

If i may recommend using craftware software as this shows the gcode and a visual representation of the

printer moves right from the start…

I know not all of these questions appear to be about the slicer software, but the slicer has a direct affect on all of the above questions…showing how important it is to get is right before you print…

let me know if you have a question about your slicer software and i aiwll see about adding it to the list above…

thanks for reading

Happy Printing