Creality offers page

This page will show you the current offers from Creality… There are different offers for different countries…so i will have links at the top to the different countries… If you know anyone who may make use of this – please…

This page will show you the current offers from Creality… There are different offers for different countries…so i will have links at the top to the different countries… If you know anyone who may make use of this – please…

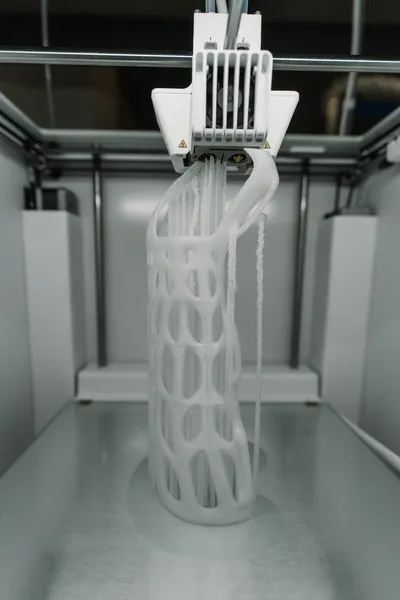

What is a 3d printer and how does it work A 3d printer is a printer that can print with an extruder in 3d rather than just 2d. So complex, impossible to machine structures can be created. Most use some…

Setting up your 3d printer is similar to printing that test page with a new printer… Setting up a temperature tower in Cura and printing it will tell you a lot about the filament and your machine… Once you have…

You slice the model you really, really want to print… You look at the time and see 21h 11min…no way…. And you will need to leave your printer on all the time… And you are going out today…. Do i…..Dare…

You have had your 3d printer a while now and printed off a few models from Thingiverse and Yeggi, maybe even some miniatures… But there are things that you want to print that there are no models for…what now… This…

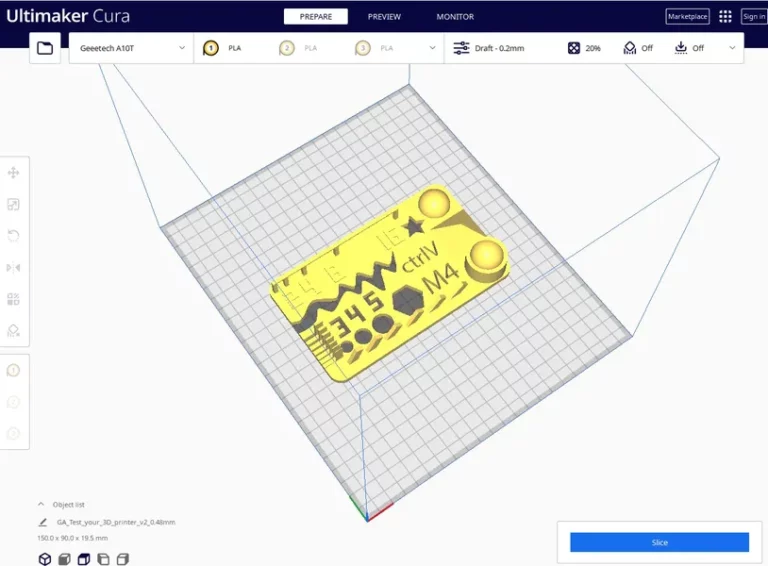

There have been a lot of questions about 3d printer slicer software, so i thought i would put pen to paper ( so to speak) and answer half a dozen of the top ones…there will be more to come… Do…

This bowden extruder mod can be carried out to any extruder which it is difficult to insert the filament into… It just happens that i have a Geeetech a10T – so i have three to do…lucky me… Why the mod-…

At the start of your printing journey you may be overwhelmed with every thing you need to do to get a good print… This guide will go through the essential settings a beginner must be aware of when using their…

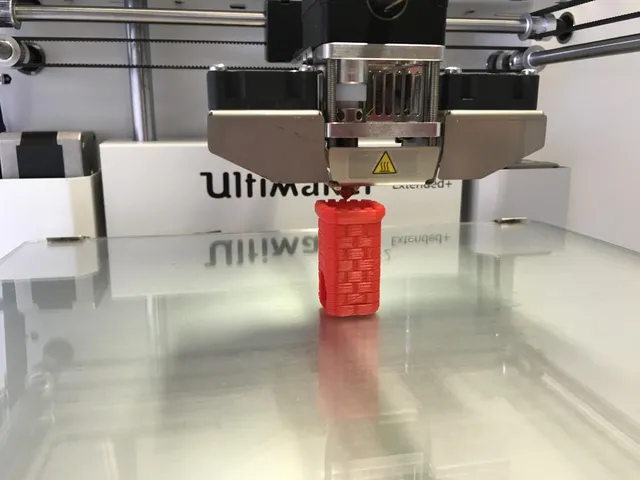

I know the excitement you feel when you get your 3d printer. That ‘ I want to print the fire dragon and it will be perfect’ thought…. I don’t want to put a dampener on it, but if you don’t…

Whether you like it or not with the 3d print process you need to incorporate slicer software within your workflow… You need a 3d slicer within your 3d print workflow because you need to translate your cad model to data…

You have bought a 3d printer…brilliant… It’s a kit, so you put it together carefully… You want it to be perfect… Ok…so all built…. Now testing the various parts… Plug it in, switch it on with eyes closed…. No bang…

A reader has Kindly generated an article to help you with your CTC printer problems. I will let you read it in his words…. by Ray J, Hereford, UK. At the start Purchased a the CTC printer through Amazon, and…

A lot of people look at the small volume of the desktop 3d printers and dream of designing a huge machine. What limits the size of a 3d printer: mechanical components , complexity and costs are the three main limitations for…

When you load your Gcode into your printer, it will carry out exactly the commands it is told. Are the default ones the best for your printer… Why customize the start g-code: Your 3d printer will do exactly what G-codes…

Do you want a smooth bottom to your prints, whether they are PLA or ABS or TPU. Well it is worth finding out how to apply Kapton tape tape to your print bed to achieve this. Applying kapton tape to…

I have now been operating 3d printers for a few years and have got used to creating models – or downloading- slicing and printing. But have recently become more and more frustrated with the Cura interface – so started looking…

Believe it or not your 3d printer is a dumb machine. It needs to be told exactly what to do and when to create those wonderful models you require from it. So how does your 3d printer know what to…

Filament problems with your 3d printer – find out what causes them and how to fix them. It’s always the case – the print that matters – you have setup the printer and made sure everything is working – you…

What is 3d printing workflow How do you get from the concept to something in your hand with an fdm printer…. What is 3d printing workflow: 3d printing workflow is the method of taking a concept of what you want and…

So you bought yourself a 3d printer …. It’s sitting on the table over there looking at you… Waiting to be used…. Now you have browsed through thingiverse ( if its up) or Yeggi to find a 3d model you…

Think it is difficult printing with the Anet A8 and TPU? Read this article to the end to find out my hints and tips Ok so you have bought an Anet A8 3d printer. You have downloaded some models from…

This article is how to find out whether your Anet A8 hotend has been assembled correctly. Common Problems with the Anet A8 hotend There are three main problems associated with the hotend which will be dealt with in this article.…

Having had my anet a8 for over a year now I am getting quite used to it. I am just going through a mod for adding an e3d v6 all metal hotend clone, with interesting results, but that’s another story.…

Which Free 3d Printing Modeling Software is Right for You? Once you have owned a 3d printer for a few months and got to know it. Downloading the latest part off Thingiverse or youmagine gets limiting, you want to explore…

One of the most frequently asked questions on the forums is how do I silence that Anet A8 fan noise? I must admit this is one of the things i really dislike about this printer…. I am lucky and have…

Anet A8 mods are an ongoing process, here is another one to add to your printer. This time it is something you may have not seen before: Adding an auxilliary socket to the Anet A8 I bought my Anet A8…

Make your Ramps 1 4 connections safe for upgrading your Anet A8 3d printer. Ramps 1 4 connections upgrade The ramps 1.4 board combined with the mega2560 is a common upgrade when the main board blows up on your Anet…

My Anet A8 bed mosfet has blown up – what now? I have been asked about this question about the anet a8 bed mosfet a few times now. So my advice was to add an external mosfet and use the…

Update to SB1 : replacing your bearings, Igus Bearings A while ago I wrote a post about replacing your bearings. SB1 In that post I had bought a set of bearings from China, they turned out to be very poor…

Happy new year to you all. Prior to the Christmas break I was printing with my Anet A8 3d printer. I had the slicer vase mode set– if you haven’t tried it you must. Vase mode produces, in some slicers,…

Service Bulletin 1 (SB1) This service bulletin details how to check and perform Anet A8 bearing replacement on the X and Y axis. What are the symptoms which require Anet A8 bearing replacement After you have bought your 3d printer…

What a digital multimeter can tell you. You know that time when your printer went wrong and you sat there looking at it? You were frustrated because you knew it was not mechanical, there was something wrong with the electrics…

How to make your own heat block cover – don’t let the cooling fan spoil your prints What Anet A8 mods have you done? All FFF 3d printers use a similar technology, the heatblock. This is the way they get…

3d print journal 01-12-17 : bed screws binding A tale of woe about the dilema to drill out the base bed screw threads or not, and what a lucky chap I am, how I overcame the problem and what you…

More Anet A8 problems Printing on the Anet A8 last night I heard a thump from upstairs, where the printer is located. Going upstairs, I found a pen on the floor – obviously not liking the vibrations of the printer.…

What Anet A8 upgrades have you done? Buying a 3d printer is exciting. Putting together an Anet A8 can be frustrating but rewarding. Printing with it is brilliant. But one problem is that you cannot see what you are printing!…

A lot of people are interested in the Anet A8 upgrades, especially the mosfet mod for the heated bed. The reason for this is a lot of misinformation out on the web about the mosfet on the main board being…

Anet A8 3d printer – A fire hazard out of the box? There has been a lot of talk on the internet about the Anet A8 problems. I disagree that it is in itself dangerous. The Anet A8 printer has…

Adding a mains socket to the anet a8 power supply The anet a8 is powered from the mains. The supplied kit has a mains lead which is connected to the anet a8 power supply directly. To switch on and off…

The Anet A8 is a cost effective introductory printer into the 3d printing world. As a build it yourself model, it is up to you how you modify it. The standard build is good and will teach you a lot…

Testing the cooling nozzles on an anet a8 Are you happy with your prints from your 3d printer? Could your cooling nozzles on your 3d printer be part of the problem? Check out what it is for and how it does…

Why would you need a UPS for a 3d printer? Why do you need a UPS for a 3d printer? Let me describe the scenario… You have spent a lot of time on your 3d printer, adding this and that…

All about a 3d print nozzle Philbest3dprinter.stan-tech.com

This Anet A8 3d printer review has been done after buying and building it, this is my third printer build – first a prusa clone, second a renren3d delta printer and this one. The 3d printing market is starting to…

Smooth PLA prints – how to achieve them Have you ever wondered how to smooth PLA prints – if so read on… You have invested money into your printer, and time if you have built it yourself. You have got…

Are you a destroyer or a detective? You know what it is like when you have 3d print problems. You come back to the printer after waiting 12 hours only to find this heap of spaghetti. ARGHHH!!!!! You rip it…

So you have bought yourself a 3d printer- excellent, now- where to place your 3d printer for the best results. With the helpful hints in this post you can be sure that if you follow them you will get the…

Build your own 3d printer kit – part 4 – programming So you want to build your own 3d printer kit, so did I – I bought the Renren3d LE kit. If you have been following along you will have…

A little while ago a friend had a problem of the build platform heating up when printer first switched on. He asked why? Make sure you are not seeing residual heat from the last print. Leave the printer on for…